C Series Concrete Mixing Equipment

Applicable scenarios: It is used in engineering projects such as highways, bridges, hydropower, ports and airports.

- Rated productivity: 60-270 m³/h

- Driving power: 2*18.5-2*75 kW

- Discharge capacity: 1000 - 4500 L

Technical features

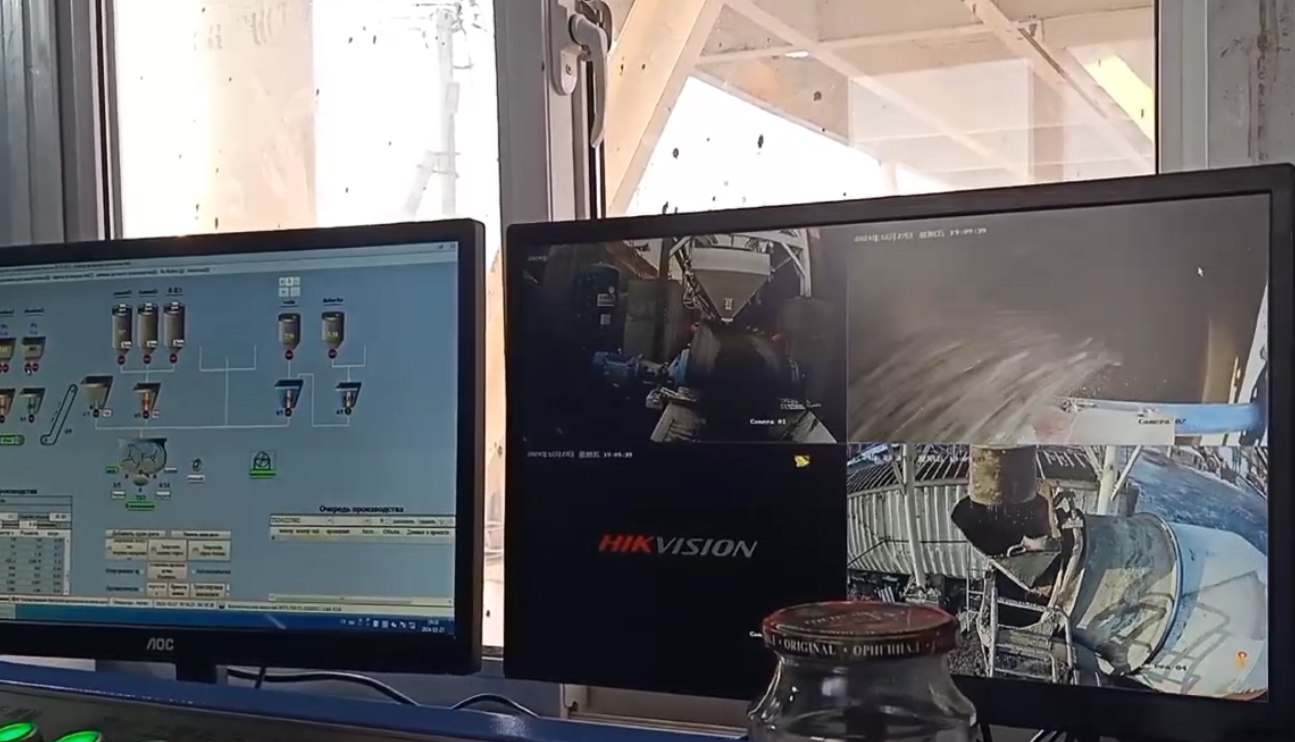

High reliability

The electrical system and the pneumatic circuit system are equipped with high-end configurations and are highly reliable.

Reusable

The exterior decoration is in a container style. It is safe and convenient for disassembly and assembly and can be reused.

Tie-rod scale structure

The powder metering adopts the tie-rod scale structure, which has high metering accuracy and strong anti-interference ability.

High productivity

The belt conveyor is used for feeding materials, and the performance is stable. The aggregate intermediate storage hopper is configured, and the equipment has high productivity.

Modular design

With a modular design, it is convenient for disassembly and assembly, quick for relocation, and flexible in site layout.

Performance parameters

| Comparison items | HZS060-3C | HZS090-3C | HZS120-3C | HZS180-3C | HZS240-3C | HZS270-3C |

| Theoretical productivity (m³/h) | 60 | 90 | 120 | 180 | 240 | 240 |

| Parameters of mixing host | ||||||

| Model | JS1000-3B | JS1500-3B | JS2000-3B | 2xJS1000-3B | 2xJS1500-3B | 2xJS2000-3B |

| Driving power (Kw) | 2X18.5 | 2X30 | 2X37 | 2X18.5 | 2X30 | 2X37 |

| Discharge capacity (L) | 1000 | 1500 | 2000 | 1000 | 1500 | 2000 |

| Maximum particle size of aggregate (crushed stone/pebble) mm | ≤60/80 | ≤60/80 | ≤60/80 | ≤60/80 | ≤60/80 | ≤60/80 |

| Batching bin | ||||||

| Bin volume (m³) | 2X150 | 2X150 | 2X300 | 2X300 | 2X300 | 2X600 |

| Hoisting motor power (Kw) | ||||||

| Belt conveyor capacity (t/h) | 200 | 300 | 400 | 200 | 300 | 400 |

| Weighing range and measurement accuracy | ||||||

| Aggregate (kg) | 3*(1000±2%) | 3*(1500±2%) | 3*(2000±2%) | 6*(1000±2%) | 6*(1500±2%) | 6*(2000±2%) |

| Cement (kg) | 500±1% | 800±1% | 1000±1% | 500±1% | 800±1% | 1000±1% |

| Fly ash (kg) | 200±1% | 300±1% | 400±1% | 200±1% | 300±1% | 400±1% |

| Mineral powder (kg) | ||||||

| Water (kg) | 200±1% | 300±1% | 400±1% | 200±1% | 300±1% | 400±1% |

| Admixture (kg) | 20±1% | 30±1% | 40±1% | 20±1% | 30±1% | 40±1% |

| Discharge height (m) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 |

| Total power of the whole machine (Kw) | 100 | 150 | 200 | 200 | 300 | 400 |

You can contact us via message or call our sales hotline