Blow bar made of modified high manganese steel prevents wear and extends its service life

High manganese seel

Material

High durability

Durability

- Accessories and Attachments

Impact crusher access-Blow Bar

PRODUCT INTRODUCTION

The blow bar is a crucial component in an impact crusher. It rotates at high speed along with the rotor. When the crusher is operating, materials are fed into the crushing chamber and are struck by the rapidly rotating blow bars. The impact force generated crushes the materials, and the crushed materials are then discharged through the discharge opening. The blow bar is mounted on the rotor using bolts or other fastening methods, and its proper installation and tightness are essential for the crusher’s efficient operation. Regular inspection and replacement of worn blow bars are necessary to maintain the crusher’s performance.

PRODUCT FEATURE

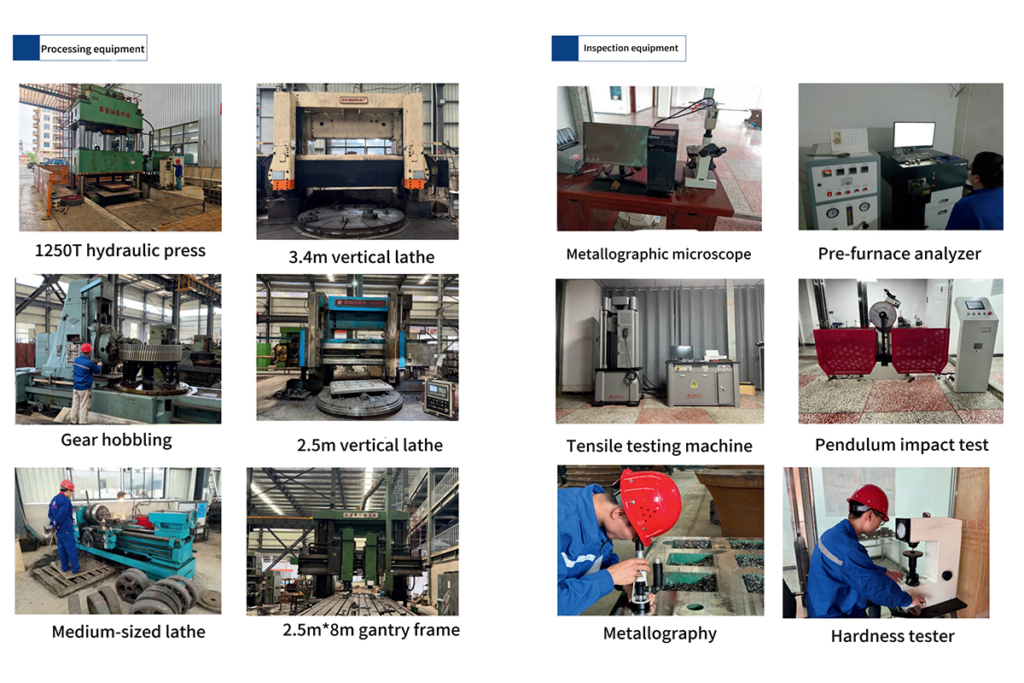

In an impact crusher, the motor drives the rotor to rotate at high speed, and the blow bars fixed on the rotor impact the materials with great force. The unique design of the blow bars, along with their high-quality material, allows for efficient crushing of various materials. OLEEK’s blow bars are made of advanced alloy materials, which offer excellent wear resistance and toughness. This not only extends the service life of the blow bars but also ensures stable and reliable operation of the crusher, reducing downtime and maintenance costs.

| Applicable Models of Impact Crusher Parts | |||||

| METSO | SANDVIK | PAXSON | NORMANSTER | KESTER | KAIRUITE |

| NP1110 | CI124 | XH250 | RM60 | R3(1011) | 4000 |

| NP1213 | CI224 | XH320 | RM70 | R5(1113) | 4800 |

| NP1315 | CI411 | XH428 | RM80 | R6(1313) | 5300 |

| NP1415 | QI240 | 4242SR | RM90 | ||

| NP1520 | QI341 | XH500 | RM100 | ||

| NP1620 | QI1441 | ||||

Related Products and Accessories

Jaw Crusher and Cone Screen – TX4

TX4 is the master in the field of crawler mobile hard rock crushing and screening. It creatively integrates four major units: vibrating feeder, jaw crusher, multi-cylinder hydraulic cone crusher, and three-layer double-layer screen to achieve the crushing and screening effect of a split hard rock production line, opening a new journey of mobile hard rock crushing.

Impact crushing and screening all-in-one machine-MI350RTE

OLEEK MI-RTE series crawler mobile crushing and screening machine can realize crushing and screening operations on one crawler vehicle at the same time. It is upgraded to oil-electric dual power and equipped with PLC one-button intelligent start. It can perform primary crushing and secondary crushing. The whole machine has a wide range of applications and a high degree of intelligence.

Crawler Mobile Sand Making Plant-MV-S

OLEEK MV-S series crawler mobile sand making station, the main machine adopts new impeller and special sealing structure, low energy consumption, long life, with external power, oil-electric integration, full hydraulic three drive modes to choose from. Suitable for sand and gravel shaping or further sand making after secondary crushing, large processing capacity, good crushing particle shape.

Crawler mobile heavy screening station-MSZ2515E

OLEEK MSZ series crawler mobile heavy-duty screening station is equipped with a plate-type high-torque feeder, a first-layer heavy-duty grid screen and a 1.2-meter ultra-wide patterned belt conveyor. It can effectively carry the screening cycle of oversized materials and is suitable for special scenarios such as soil-rock separation and preliminary screening of construction waste, with particularly good results.

Crawler Mobile Screening Station-MS3618

OLEEK MS series crawler mobile screening station is equipped with a vehicle-mounted fully automatic folding belt conveyor. It has a large processing capacity and can perform fine screening of materials. It is suitable for screening finished materials after crushing various sand and gravel and construction waste. The overall transportation is flexible, durable and highly reliable.

Perfect Solid Waste Solution

For special requirements, we offer the custom-made solution!